Supply chain management plays a crucial role in the success of businesses across various industries. A well-designed and efficiently executed supply chain management system is essential for companies to optimize their operations, reduce costs, and deliver products or services to customers in a timely manner.

In this article, we will delve into the key components that constitute a robust supply chain management system, highlighting the importance of each component in ensuring a smooth and efficient flow of goods and services.

- Planning and Forecasting

Efficient supply chain management begins with effective planning and forecasting. This component involves analyzing market trends, demand patterns, and historical data to develop accurate sales forecasts and production plans. By aligning production and inventory levels with anticipated demand, companies can minimize stockouts and excess inventory, thus reducing costs and maximizing customer satisfaction.

- Procurement and Vendor Management

Procurement and vendor management focus on sourcing and selecting suppliers, negotiating contracts, and establishing mutually beneficial relationships. It is crucial to work with reliable and quality-focused vendors to ensure a steady supply of materials or components at competitive prices. Effective vendor management also involves monitoring supplier performance, managing relationships, and implementing strategies for risk mitigation.

- Inventory Management

Inventory management is a critical component of supply chain management. It involves optimizing inventory levels to meet customer demand while minimizing carrying costs. Advanced inventory management techniques, such as just-in-time (JIT) inventory systems and demand-driven replenishment, help organizations reduce excess inventory, improve cash flow, and enhance overall operational efficiency.

- Transportation and Logistics

The transportation and logistics component encompasses the movement of goods from suppliers to customers. It includes selecting the appropriate transportation modes, optimizing routes, managing shipping and freight forwarding, and tracking shipments in real-time. Efficient transportation and logistics operations ensure timely delivery, minimize transportation costs, and enhance customer satisfaction.

- Warehouse and Distribution Management

Warehouse and distribution management focuses on the effective storage, handling, and distribution of products. It involves optimizing warehouse layouts, implementing efficient order fulfillment processes, and utilizing technology-driven solutions, such as barcode scanning and automated inventory management systems. Well-managed warehouses and distribution centers enable companies to reduce order processing times, improve order accuracy, and enhance overall supply chain efficiency.

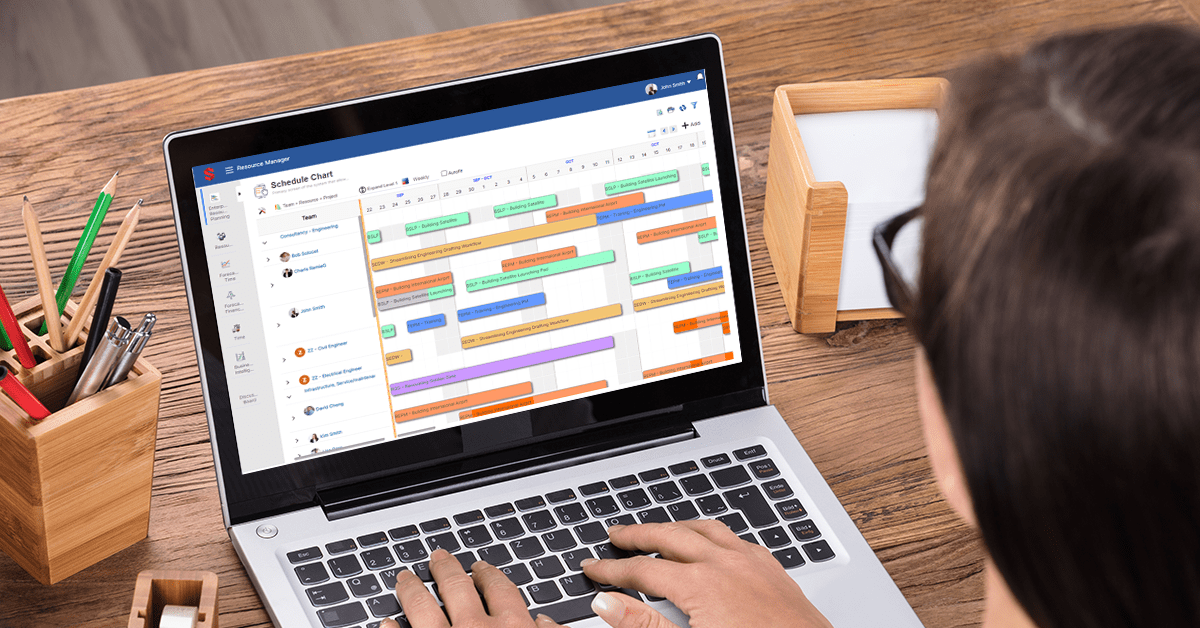

- Information Technology and Data Analytics

Information technology and data analytics have revolutionized supply chain management. Advanced software systems and data analytics tools enable companies to collect, analyze, and utilize vast amounts of data to make informed decisions. Supply chain analytics can provide valuable insights into demand patterns, supply chain performance, and potential bottlenecks, enabling proactive decision-making and optimization.

- Collaboration and Communication

Collaboration and communication are essential for effective supply chain management. Building strong relationships with suppliers, customers, and other stakeholders fosters collaboration and enables seamless information sharing. Collaboration platforms and technologies facilitate real-time communication, enabling timely responses to changing market conditions and ensuring alignment across the supply chain.

- Risk Management

Supply chain disruptions can have significant negative impacts on business operations. Risk management involves identifying potential risks, developing contingency plans, and implementing strategies to mitigate risks. By proactively addressing risks, such as natural disasters, political instability, or supplier bankruptcies, companies can minimize the impact on their supply chains and maintain business continuity.

- Sustainability and Ethical Practices

In today’s environmentally conscious world, sustainability and ethical practices are becoming increasingly important in supply chain management. Companies are expected to adopt sustainable sourcing, reduce carbon footprints, and promote ethical labor practices. Integrating sustainability into the supply chain not only aligns with societal expectations but also enhances brand reputation and reduces long-term risks.

- Performance Measurement and Continuous Improvement

To ensure the effectiveness of a supply chain management system, companies must measure key performance indicators (KPIs) and continuously strive for improvement. By tracking metrics such as on-time delivery, order accuracy, and inventory turnover, organizations can identify areas for enhancement and implement targeted improvements. Regular performance reviews and feedback loops enable companies to adapt to changing market dynamics and maintain a competitive edge.

Conclusion

A robust supply chain management system comprises various interconnected components that work together to optimize operations and enhance customer satisfaction. From planning and forecasting to performance measurement and continuous improvement, each component plays a vital role in ensuring an efficient and responsive supply chain. By investing in these key components and adopting best practices, companies can gain a competitive advantage in today’s dynamic business environment.